Climate change and the consequent increase of dangerous atmospheric events have pushed civil engineering to develop new sustainable systems for the treatment of rainwater.

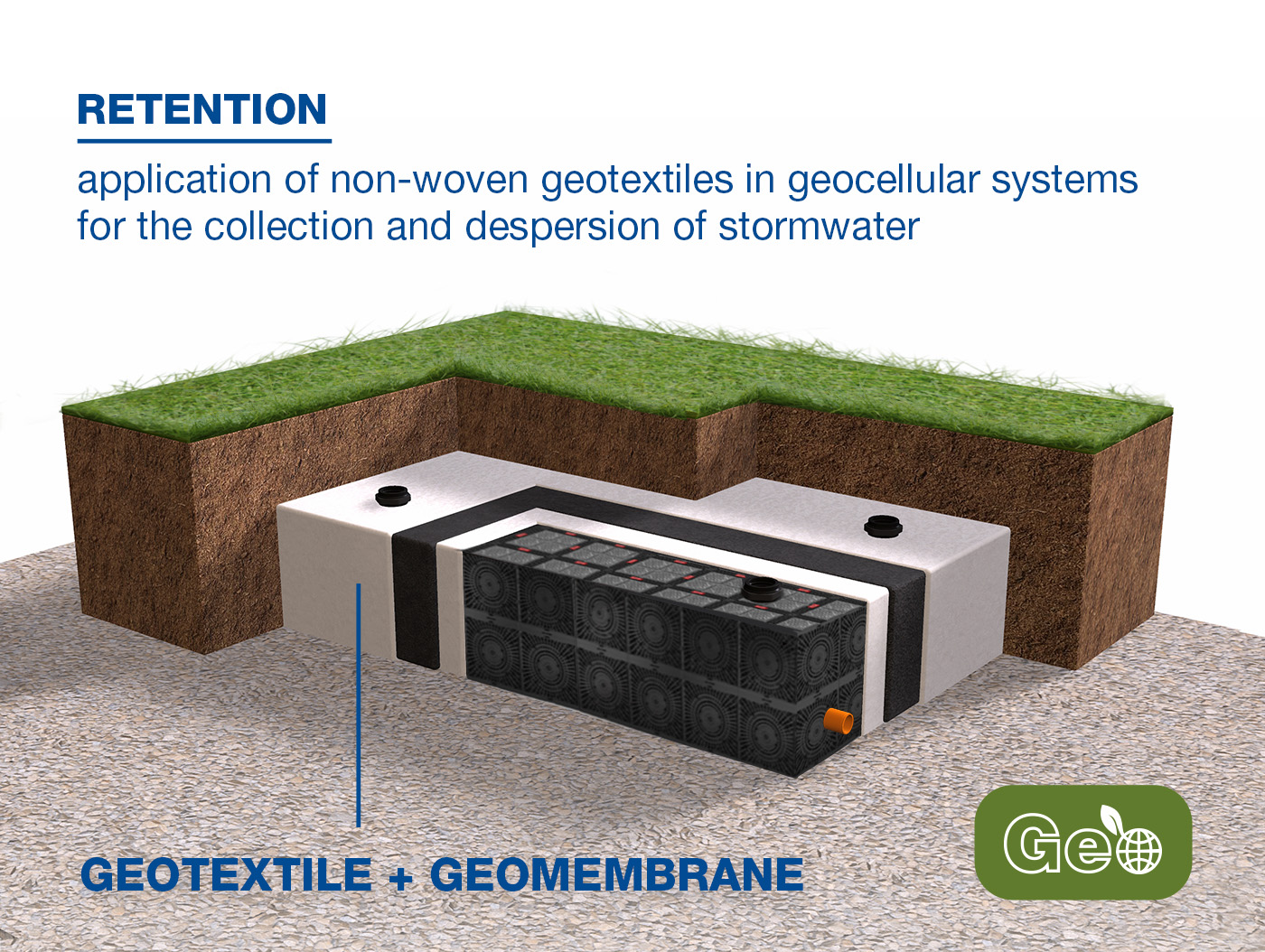

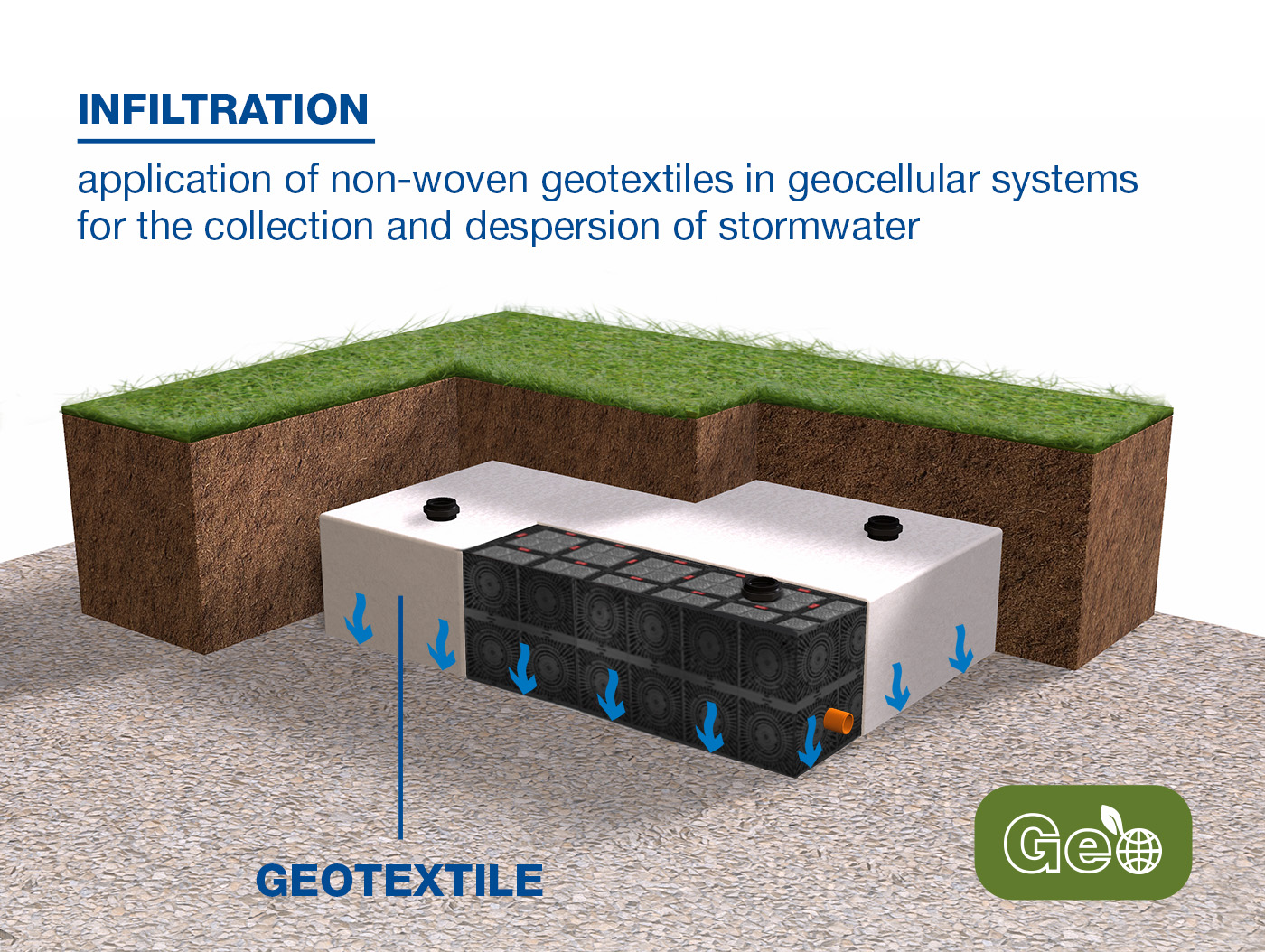

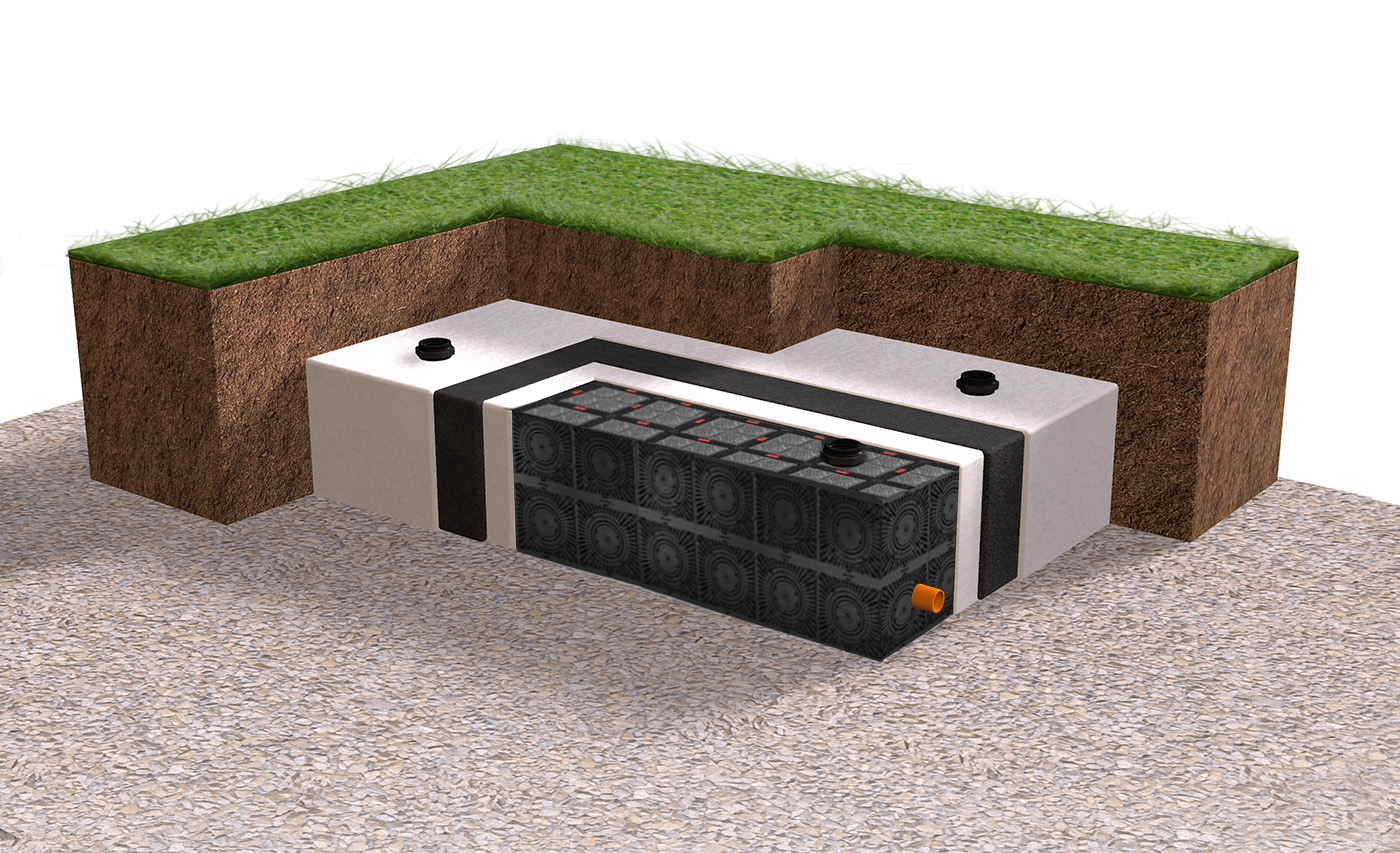

In this regard, we analyze the use of non-woven geotextiles in the installation of modular systems to create

Sustainable urban Drainage Systems (SuDS), solutions designed to reduce the potential impact of sudden and heavy rains in highly urbanized areas and to protect and improve water quality.

We refer: Retention tanks or infiltration tanks

In the first case, the geotextile performs the filtration function and protects the membrane used to guarantee storage; in the second case it performs the filtration function.

The combined use of drainage modules, membrane and non-woven geotextile

1. Reduces the excavation by 1/3

2. Increases retention capacity 3 times compared to traditional gravel

3. It guarantees saving of natural resources

4. Reduces the use of heavy vehicles on site and the consequent environmental impact

5. Increases safety on site due to easy installation

6. Guarantees versatility

The solutions offered by modular stormwater systems are

• the storage of rain for domestic reuse, irrigation, to clean the streets ...

• drainage of industrial and commercial areas

• storage and drainage basins

SuDS can be established at the level of

- basin

- city

- residential district

- single building

For example, to create new industrial or residential districts in areas where sewers are at the limit of their capacity, these systems represent an effective and easy alternative to be installed.

Italiano

Italiano  English

English