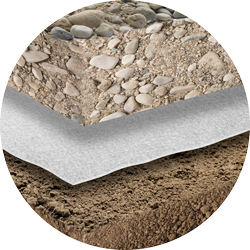

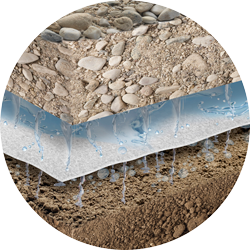

It is a non-woven geotextile made by high tenacity polypropylene staple fibres, needle-punched and/or thermocalandered, without resins or glues, UV stabilized. It is not toxic and does not pollute the environment. It is resistant to alkalis, acids and organic substances. Moulds, rodents and microorganisms cannot attack GEO. Its qualities and properties are not substantially modified by climatic factors like frost, heat, humidity etc.

TECHNICAL FEATURES

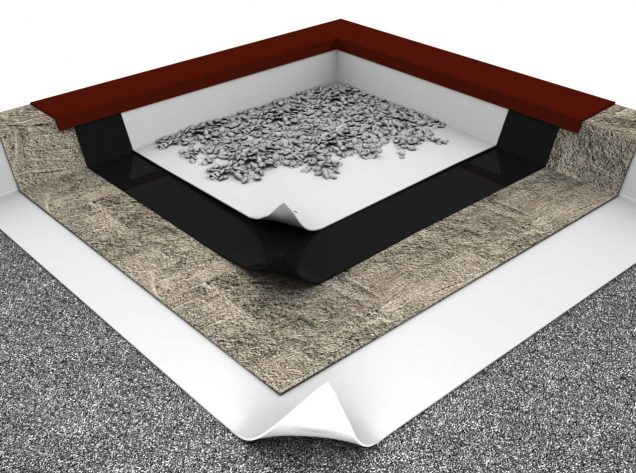

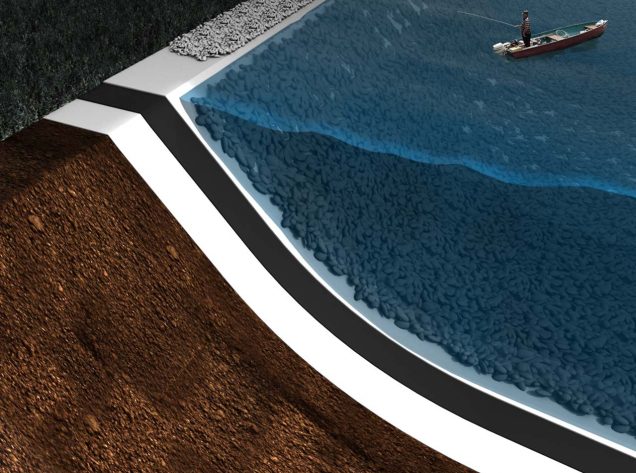

- USE: as separation and filtration layer.

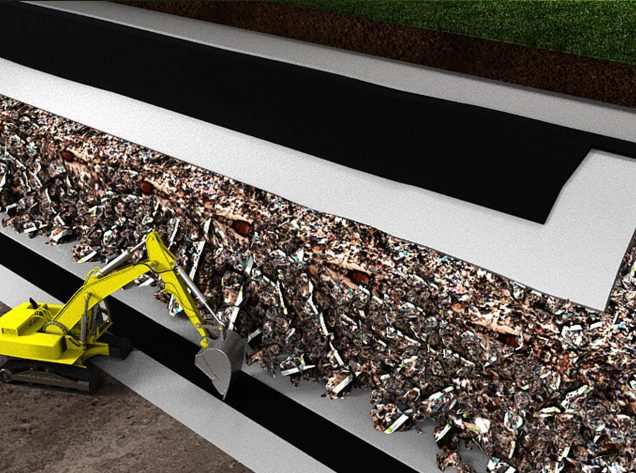

- INSTALLATION: in the erosion control works of coasts, riverbanks, canals, between the base soil and the permeable revetment (rock blocks, rip-raps, gabions).

- REFERENCE STANDARD: EN 13253 (Geotextiles and geotextile-related products. Characteristics required for use in erosion control works (coastal protection, bank revetments).

- RELEVANT CHARACTERISTICS: tensile strength, static and dynamic puncture resistance, permeability normal to the plane, characteristic opening size, durability.

- RECOMMENDED PRODUCTS: to be chosen according to the characteristics of subsoil, to the type of revetment blocks, and to the dropping height of blocks installed on the nonwoven. For example, with dropping height over 1 m and a weight of blocks over 1000 – 15000 – 2000 kg respectively, GEO PP AG 500 – 600 – 700 g/m2 should be used.

UNIT WEIGHT: 500 - 700 g/m2

ROLL SIZE: max roll width 650 cm

- CE MARKING

In our internal laboratory the mechanical and hydraulic characteristics of the final product are tested, as well as the quality of the fibre.

Italiano

Italiano  English

English